What to Look for When Choosing the Best Heat Sealing Machine for Your Business Needs

Choosing the right heat sealing machine for your business is a critical decision that can significantly impact your production efficiency and product integrity. According to a report by MarketsandMarkets, the global heat sealing packaging market is projected to reach $15.2 billion by 2025, reflecting a compound annual growth rate of 5.3%. This growth underscores the increasing demand for reliable and efficient packaging solutions across various industries, including food, pharmaceuticals, and electronics. A suitable heat sealing machine should not only align with your production needs but also offer flexibility, durability, and energy efficiency. As multiple alternatives exist in the market, understanding the specific application requirements and the available technology can help businesses make informed choices that enhance productivity and reduce operational costs.

Key Features to Consider in a Heat Sealing Machine

When choosing a heat sealing machine for your business, several key features must be considered to ensure you are making the best investment. First, examine the sealing width required for your products. Different machines offer various sealing widths, and selecting one that accommodates the size of your packages can enhance efficiency and minimize waste. Additionally, consider the thickness of the materials you will be sealing. A machine with adjustable settings can effectively handle a range of material types, ensuring a secure seal every time.

Another critical feature is temperature control. Precise temperature settings allow you to adapt to different materials and seal types. Look for a machine with digital controls, as they provide more accuracy and consistency, reducing the risk of overheating or under-sealing your packages.

Tip: Always check user reviews and seek recommendations from industry peers to identify reliable brands known for their durability and performance. Investing in a machine with a good warranty can also safeguard your business against unforeseen issues down the line.

What to Look for When Choosing the Best Heat Sealing Machine for Your Business Needs - Key Features to Consider in a Heat Sealing Machine

| Feature | Description | Importance |

|---|---|---|

| Heating Mechanism | Types include direct, conductive, and infrared heating. | Essential for determining sealing efficiency and quality. |

| Temperature Control | Digital or analog controls for precise temperature management. | Critical for different materials and sealing requirements. |

| Speed | Measured in seals per minute; influences productivity. | Important for meeting production deadlines. |

| Size and Capacity | The size of the sealing area impacts the size of products that can be sealed. | Vital for accommodating various product dimensions. |

| Durability | Quality of materials and construction that affect long-term usage. | Essential for reducing replacement costs. |

| Energy Efficiency | Rating to assess consumption of electricity during operation. | Important for cost-effective operations. |

Types of Heat Sealing Machines and Their Applications

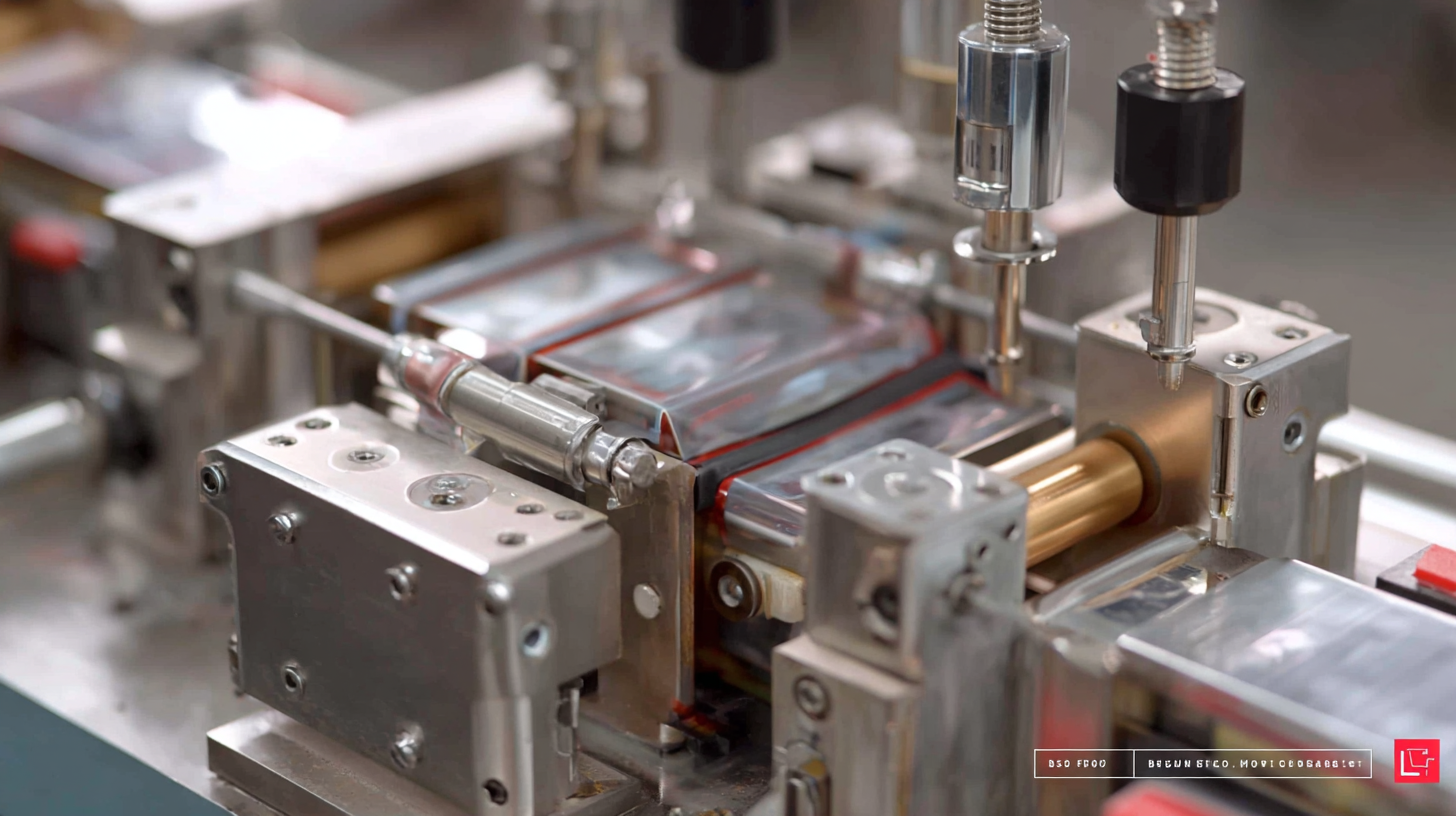

When selecting a heat sealing machine, it's crucial to understand the various types available and their specific applications. Heat sealing machines generally fall into categories such as continuous, impulse, and band sealing machines. Continuous sealing machines are ideal for high-volume production and can efficiently seal packaging materials in a continuous feed process. They are often used in food packaging, ensuring airtight seals for perishable items.

Impulse sealers, in contrast, are more versatile and suitable for smaller operations or businesses that require occasional sealing. These machines use a heated wire that activates upon closing the sealing jaws, creating strong seals on a range of materials, including plastics and aluminum foil. Impulse sealers are commonly employed in retail for sealing bags or custom orders.

Band sealers, utilizing a conveyor system, allow for the simultaneous sealing and cooling of packages, making them perfect for integrated production lines. They are particularly beneficial for sealing products that require an extended cooling period before distribution. Understanding these different types can help businesses choose the right machine tailored to their specific sealing needs, enhancing productivity and product integrity.

Assessing Your Business Volume and Sealing Requirements

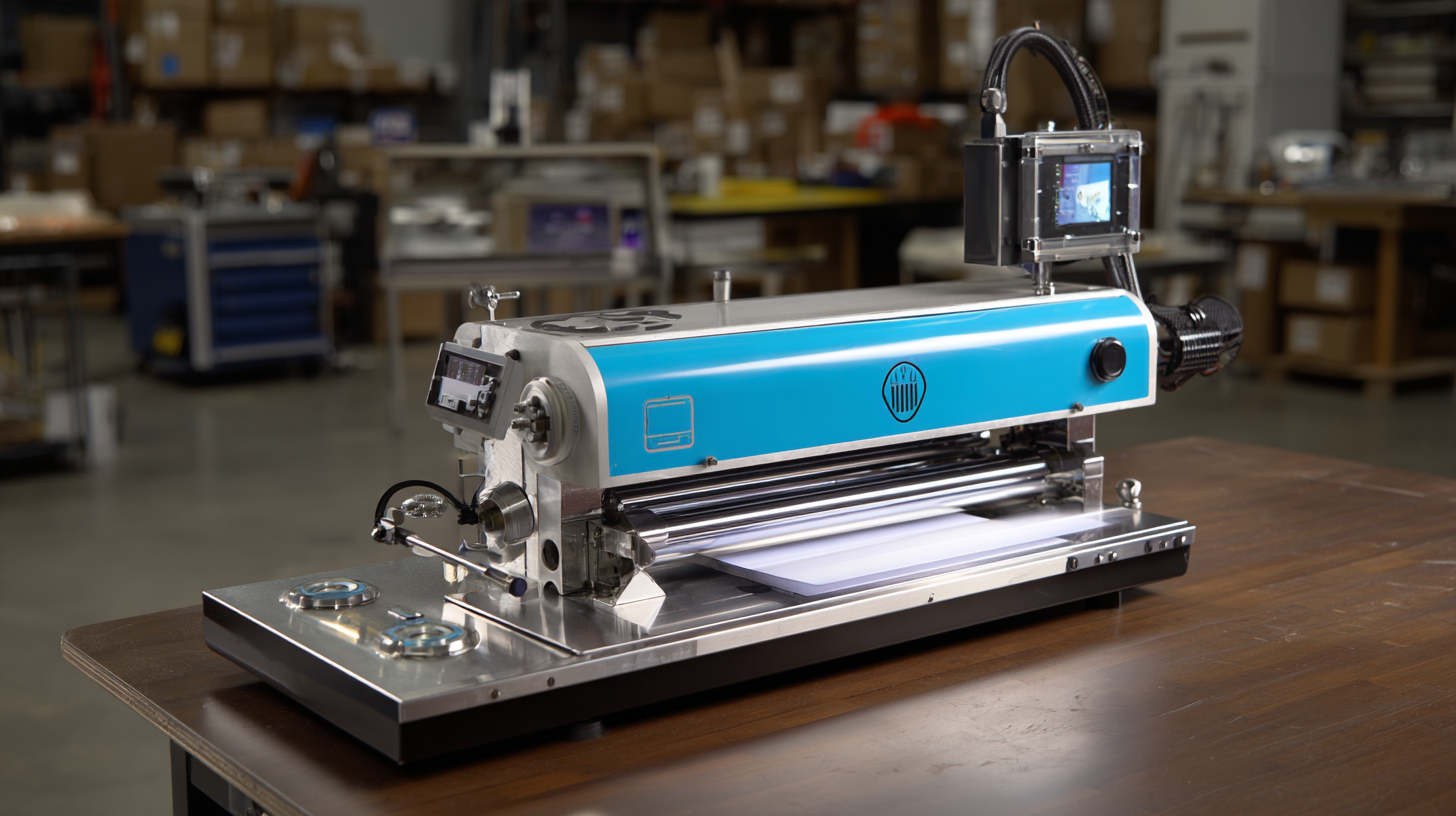

When selecting the best heat sealing machine for your business, it is essential to assess your business volume and sealing requirements first. Understanding the scale of your operations will guide you in choosing a machine that meets your production needs without overextending your budget. For instance, high-volume businesses may require more robust, industrial-grade machines capable of handling continuous production, while smaller businesses might benefit from compact, less expensive models that still provide reliable sealing capabilities.

In addition to volume, consider the specific sealing requirements of your products. Different materials and packaging styles may dictate which type of heat sealing technology is most suitable. For instance, if your products require airtight seals or are sensitive to temperature variations, choosing a machine with adjustable settings may be crucial. Evaluating the characteristics of what you’re sealing—such as thickness, material type, and desired seal strength—ensures that you invest in equipment that enhances efficiency and product integrity while minimizing waste and operational costs.

Assessing Business Volume and Sealing Requirements

Budgeting for Quality: Costs of Heat Sealing Machines

When selecting the best heat sealing machine for your business, budgeting for quality is essential. While it may be tempting to opt for the least expensive option, investing in a reliable machine can save you money in the long run. The initial cost should be weighed against factors such as durability, efficiency, and the quality of seals produced. Budget-friendly models often come with trade-offs in performance or longevity, making it crucial to establish a budget that balances affordability with the required features for your specific applications.

Moreover, understanding the costs associated with different types of heat sealing machines can help you make a more informed decision. Explore options available in various price ranges, as there are models that cater to different budgets without compromising on essential capabilities. Look for machines that offer a good warranty, robust customer support, and high user ratings. Doing your research encourages investing in a heat sealing machine that meets your business needs effectively, ensuring that you achieve operational efficiency and high-quality results.

Maintenance and Support: Ensuring Longevity of Your Equipment

When selecting a heat sealing machine for your business, maintenance and support are crucial factors that can significantly impact the longevity and efficiency of your equipment. Regular maintenance routines should be established to keep the machine in optimal working condition. This includes daily inspections of components such as the heating element, sealing jaws, and pressure mechanisms. Over time, wear and tear can affect performance, leading to inconsistent seals and wasted materials. Scheduling routine maintenance checks with certified technicians can help identify potential issues before they become major problems, ensuring smooth operations.

Moreover, strong manufacturer support is vital for any heat sealing machine. A reliable supplier should offer comprehensive service packages that include training, troubleshooting assistance, and access to spare parts. Being able to quickly resolve operational issues minimizes downtime, which is essential for maintaining productivity in a fast-paced business environment. When choosing your heat sealing machine, consider the availability of customer support and the range of maintenance services offered. This investment in ongoing support will help extend the life of your equipment and enhance your production capabilities.